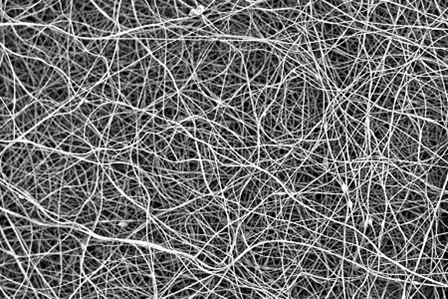

Nanotechnology has developed at unprecedented levels during the last decades. One of the materials that has reached a broader range of applications is the nanofibers, a type of nanomaterials with cross section dimensions in the range of nanometers, about ten to a couple of hundreds. These nanofibers feature high specific area-to-volume rates and their main applications comprise from filtration, textile and pharmaceutical manufacturing to biochemical tissue development.

A great future awaits to these nanofibers, since there has been promising development in the energy field as well, with applications in batteries and fuel cells, solar cells and capacitors.

It all starts with a single thread

One of the most advanced nanofiber production technique is the electrospinning, in which a charged polymer solution is drawn by electrostatic repulsion. This takes place at a nozzle (emitter) that feeds polymer droplets that keep balance between their surface tension and the electrostatic repulsion. As polymer cohesion maintains, a cone first and then a long solid fiber forms, as the solution progressively dehydrates.

This is an ultra-high precision technique carried out by sophisticated equipment using state of the art computer-controlled processes. An electrospinning machine manufacturer must have the ability and background knowledge to develop cutting-edge technology devices capable of generating laboratory-grade nanofibers to be used in a wide range of applications, mainly in, but not limited to, the health and biomedical fields.

Controlling parameters

The electrospinning process may sound simple as it was developed, but it has a lot of different factors that must be precisely controlled to achieve highest-grade nanofibers, particularly those aimed to biomedicine, for instance, to develop synthetic skin or other replacements to human tissues.

The main physical aspects involved are:

- Molecular properties of the polymer

- Conductivity, surface tension and viscosity of the solution

- Needle/nozzle gauge: depends on the viscosity of the solution.

- Electric potential: higher voltage forms thicker fibers.

- Size and motion of the collector (target screen)

- Separation between the emitter nozzle and the collector: larger distances means higher dehydration, fibers may crack.

- Ambient temperature and humidity: may cause beads and pores in the surface.

All these complex parameters must be taken care of with the highest precision, inside a machine that in most cases features an array of up to 20 emitter nozzles for increased performance. A real piece of engineering.

By controlling some of those parameters these machines are capable of producing particles by electrospraying, which is a technique derived from electrospinning, to get a flow of polymer nanoparticles instead of a single fiber.

Applications of electrospun nanofibers

There is a growing range of applications for the nanofibers and the tissues elaborated with them, as stated above. A short list, by type of field, includes:

Biomedical

The similar structure of the electrospun fibers compared to some human tissues make the former an ideal complement or substitution for some of them. Some uses are:

- Skin replacement: in wounds, burned and lacerated skin. Fibers are electrospun from bioresorbable materials that absorb fluids from the injured area without the need of later removal.

- Regenerative medicine: it helps in-vitro growing of some human body veins, tendons, bones and other tissues.

- Implant coating: electrospun fibers are used to add an antimicrobial layer that prevents infections of implants, like joints or dental pieces.

Energy

Different uses can have the nanofibers in emerging energy generation and storage technologies:

- Solar cells: One-dimensional nanofibers have shorter electron transport paths, giving better charge transport qualities. Transparent solar cells can be made with them.

- Fuel cells and batteries: Nanofibers could be an ideal electrode material for energy storage devices, such as batteries and fuel cells, thanks to their relatively large specific surface area and great porosity, appropriate for storing electrolytes and helping quick and longer term electron/ion transport.

Pharmaceuticals

The electrospinning and electrospraying techniques have a wide field in the pharmaceutical industry, for encapsulation of APIs (active pharmaceutical ingredients), i.e. the components of a drug. Particles and fibers are used as a support for the controlled release of that active components into the human body.

Conclusions

Electrospinning, a technique that had been developed from white-paper theory in the mid-60s to the first prototypes during the last decade of the 20th century is now an outstanding high-precision tool that helps many fields in the industry and a promise of remarkable evolution.