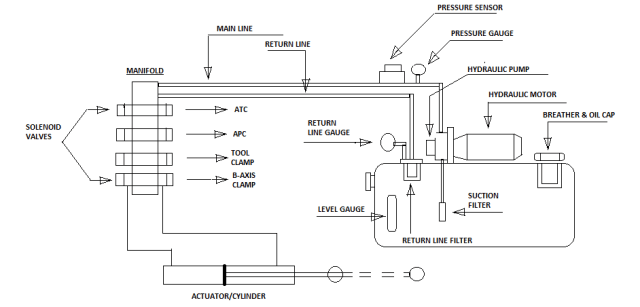

Hydraulic system is nothing but a system operated by hydraulic oil. When there is a need of much pressure in low volumetric area, Hydraulic system gives us the solution. CNC machine is such type of machine where several jobs are executed in compact area and in less time. In such scenario, hydraulic systems play a big role to execute several functions. Hydraulic Pressure in CNC machine is developed by hydraulic power pack which is a combination of several hydraulic components. Hydraulic circuit is a close circuit. A hydraulic pump is incorporated to raise the pressure up to desired system pressure and that system pressure is distributed to various work places through solenoid valves and regulated through hydraulic pressure regulators.

Top 5 Use of Hydraulic System In CNC Machine

Hydraulic system in CNC machine is controlled by a hydraulic power pack.hydraulic power pack design is so important for better working of the hydraulic systems.

1. Tool clamp/declamp operation :

Spindle hold the cutting tools in both milling and turning center. Tools get fixed in the spindle through the draw bar or draw tube and spring catcher or ball catcher. Actually clamp operation is generally disc-spring operated and during clamp operation tool is pulled through draw bar or draw tube with the disc springs. So the hydraulic system get involved in the time of declamp, when the the total unit is pushed against the disc springs through a hydraulic cylinder. In some cases both the clamp and declamp operations are operated by hydraulic system.

2. Pallet clamp/declamp operation :

Job is held firmly through the fixture which is positioned on the work pallet. So during the cutting operation the pallet should be fixed firmly. This fixation of pallet is confirmed by hydraulic clamping. Hydraulically operated ball catcher hold firmly the cones of pallet and during pallet changing the ball catcher releases.

3. Hydro-motor for arm rotation or turret rotation:

For most of the cases Servo motor or induction motor is used in CNC machines for rotational operation. but for some cases where positional feed back and breaking is not so necessary, hydraulically operated hydro motor is used for rotation. Such as turret rotation in turning center where hydro motor is incorporated with geneva wheel and gear train.

4. Hydraulic hammer for hot and cold swagging :

Cold or hot swagging machine is used for reducing the dia and enlarging the length of work piece.No. Of hammers are used to solve this purpose. The main hammering operation is controlled by an induction motor through gear train and crank shaft, but the initial opening and closing of the forging hammer is hydraulically operated.

5. Rotational axis clamp/declamp :

Rotational axis of CNC machine (a axis, b axis or c axis) are needed to be declamped before rotation. Those axis have to be clamped firmly in the definite degree in order to perform perfect cutting. These clamp and declamp operation is performed hydraulically. A hydraulic cylinder is incorporated for clamping and declamping the axis.

So those are the use of hydraulics system in CNC machine. Apart from those, many other important operations are executed through hydraulic circuit.

You may like 5 features of CNC machine.