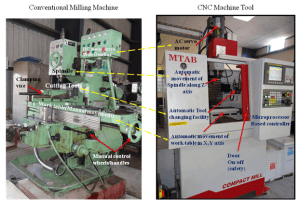

Computer numerical control machine tools are such type of machine tools that have revolutionized machining processes. It is nothing but using a computer as a mean to control a machine that produces useful objects from solid blocks of material. CNC machine works under a closed loop system, that means when it operates by executing a program, feedback is coming back to the CNC system. But the above is not a detailed answer for what is CNC machine.

If we start with a material block in a CNC machine after a specific time machine gives us a finished product like a spur gear, rifle barrel, etc. Thus we can see that CNC machine performs various jobs on a single machine tool.

A brief description of CNC systems :

Let’s find the CNC machine definition, CNC system and CNC technology in a descriptive manner.

1. What is CNC Machine :

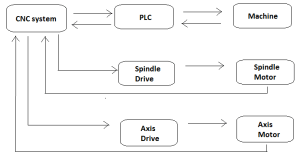

The full form of CNC is Computer numerical control. If we want to produce a finished product from a block, we have to undergo some chromatic operations. Those operations are performed one by one by Programmable Logic Controller (PLC) in CNC machine. There are some theoretical program commands which were pre-arranged in a storage medium.When those programs are executed, the operations are performed one by one.

2. The advantage of CNC machine :

Modern industry uses the CNC machine not only for reducing the production cost but also it saves the time and increase the profit and accuracy of the job. CNC machine is most useful for complex machining. Not only the metal works, CNC machine is used for woodworking also as a single machine tool.

To keep pace with the modern world, machine tool industries are introducing computerization by a CNC machine, which has the flexibility in design and production. Earlier CNC machines were applied as general conventional machines like lathe, milling machines, etc. Later the CNC machines are used for added efficiency in all sectors of production like milling, turning, grinding, drilling, threading, tapping, punching, nibbling, etc. Now the introduction of automatic tool changers, Automatic pallet changer in a CNC machine, makes machining operation faster and reduces the loss of machine time.In a “Universal Machining Center”, introduction of two spindles(one horizontal & one vertical) complete machining is possible for five exposed faces of a cubical component in a single set up. Another type of machine is “Flexible Manufacturing System” or FMS consisting one or more CNC machines are operated under a control of central computer are available. These types introduce some extra features like automatic component load/unload station, automated material, handling system, component measuring system, wash station, etc. which increases the productivity & higher machine utilization using less human resources.

3. How CNC machines work :

In CNC system a dedicated computer is used to perform all the essential functions as per the executive program stored in the computer memory. The system directs commands to servo drives to drive the servo motor & other output devices like relays, solenoids, etc. to initiate the operations such as motor starting & stopping, coolant on & off, tool changing, pallet changing, etc. and other miscellaneous functions. Once the system gives, it becomes necessary to ensure that the particular function has been completed. This is done by “Feed Back Devices.” Continuous feedback device like linear scale, encoder, resolver, etc. are used as a position feedback of the motor. Some sensors like proximity switch, limit switch, pressure switch, flow switch and float switch, etc. are used as feedback devices to monitor the different operations.Thus all operations of CNC machine are monitored continuously with appropriate feedback devices. So that CNC system is called as “Closed Loop” system. In case of failure in any failure feedback, the system generates a “Fault Message.”

4. Different types of CNC machines :

Nowadays in modern industry, there are six kinds of CNC machines are used. Those are CNC milling, CNC lathe, CNC laser cutting, CNC plasma cutting, CNC router and CNC 3D printer. CNC milling is again classified into horizontal and vertical machining centers. Concerning the presence of the number of axis in a machine, There are 3 axes, 4 axes, 5 axis and multi-axis CNC machines can be found.

5. Constructional features of CNC Machine :

Constructional features of CNC machines are :

- Structure

- Slide Ways

- Spindle Drives

- Feed drives

- Position measuring devices

- Automatic tool clamping and work clamping

- Tool magazines and auto tool changers

- Automatic work changers

- Special features

- Lubrication

- Coolant systems

- Chip handling systems

In the world of competition, various companies like Tornos, Moore, willemin Macodel etc. are trying to develop better accuracy to perform the precise work.

Please Leave your valuable comment if you find this topic useful. You may also check Top mechanical companies in India.

Hello. CNC machining parts is suitable for engineering-grade plastic and metal parts and can be used to make from one single prototype up to hundreds parts. We offer the production of precision-machined components. Our precision engineering department offers milling, CNC engineering, surface grinding, wire cut, mirror EDM erosion and more.Fastest deliver time, as soon as 15 days tooling +3 days deliver for whole set of mold parts.